Scopri come produrre un pesto di basilico omogeneo e dal sapore autentico: rispecchia la qualità artigianale su una produzione industriale con Pro

Cut Easy

Multi-Purpose Vacuum Cooker ProCut for Maxigourmet

Ti raccontiamo l’esperienza di Maxigourmet con il nostro cuocitore sottovuoto multiuso Procut per la produzione di sughi e salse.

Continue readingWe Prepare Cheese Cream with the Pro Cut Easy Industrial Cooker

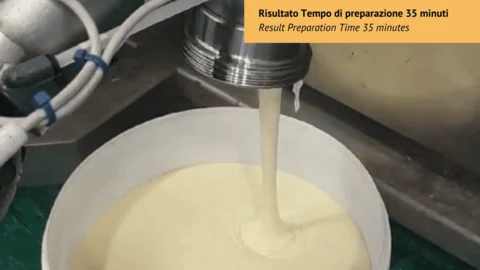

How the Pro Cut Easy Industrial Cooker Creates Cheese Cream in 35 minutes.

Continue readingIce Cream Mix Storage and Maturation Plant with a Capacity of 70,000 Liters

Scopri il sistema di miscelazione Inox-Fer per la produzione di prodotti chimici nel trattamento delle acque.

Continue readingCustom Mixing System for Water Treatment Chemical Production

Discover more on the custom mixing system for water treatment chemical production.

Continue readingLet’s test the potential of ProCut Easy preparing custard

La nostra ricetta per una crema pasticcera di qualità in soli 45 minuti.

Continue readingTailored-made Jacketed Kettle for viscous foods

For one of our international partners specialized in the production of highly viscous foods, such as soy, we have designed and built a custom jacketed kettle with a capacity of 550 litres after a thorough analysis.

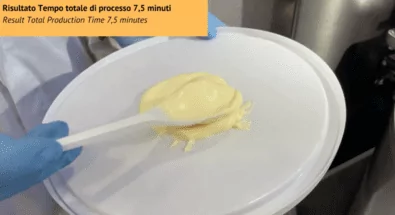

Continue readingLet’s prepare the mayonnaise with ProCut Easy Industrial Vacuum Cooker

La maionese è una preparazione versatile: scoprila ricetta per evitare grumi e ottenere un prodotto di alta qualità con il nostro cucitore industriale.

Continue readingIndustrial vacuum cookers: exploring new recipes, making béchamel sauce

Nella nostra linea di cuocitori industriali si fondono efficienza e versatilità: ecco la nostra ricetta per la preparazione della besciamella su ProCut Easy.

Continue readingIndustrial vacuum cookers: exploring new recipes, making hummus

Our line of industrial cookers combines efficiency and versatility: here is our recipe for preparing hummus on ProCut Easy.

Continue reading